- Process expertise, digital tools and automation systems

- Low-emission technologies

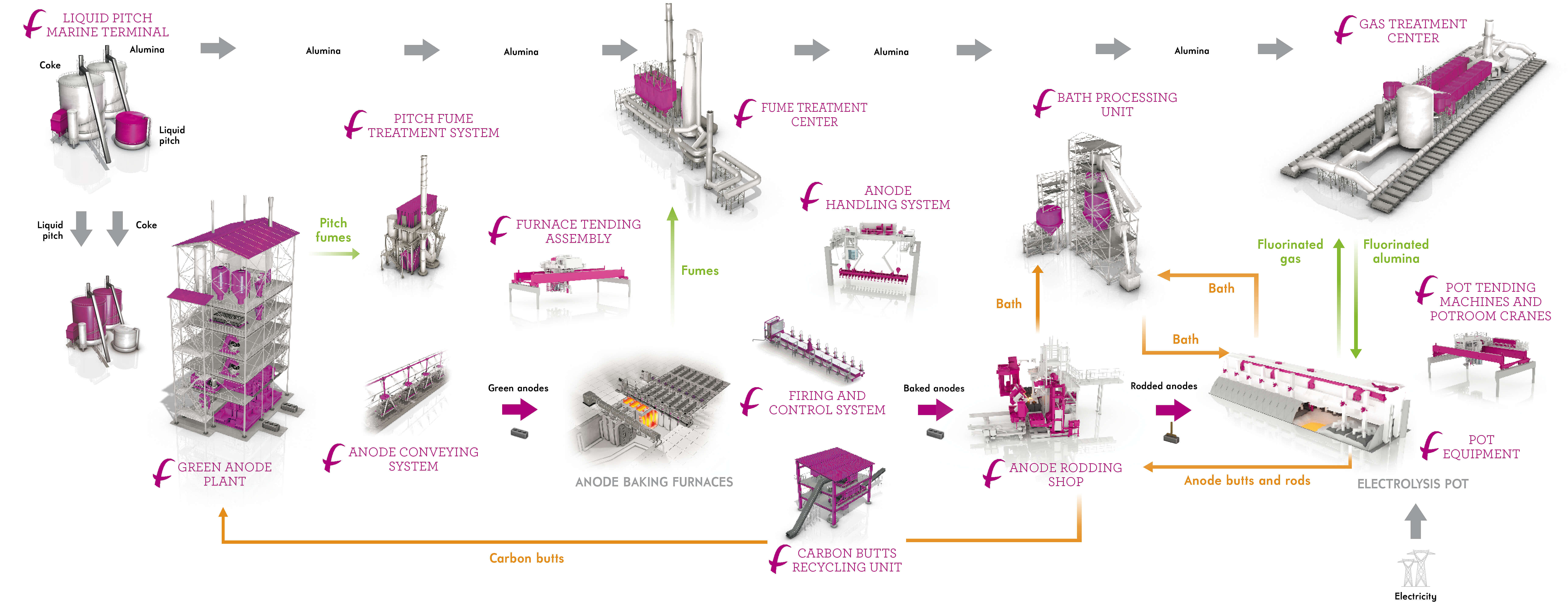

- State-of-the-art solutions for primary aluminium production

- High performing solution to treat emissions from cement, minerals, waste-to-enery and syngas industries

- Lifting and Handling equipment

- Services: upgrade, on-site assistance, remote monitoring

ALUMINIUM | AIR POLLUTION | LIFTING HANDLING NEWS

LEARN ABOUT ALL OF OUR LATEST NEWS AND EVENTS

On 18th February, in the presence of Aluminium Bahrain B.S.C. (Alba)’s management team, Fives Services Gulf inaugurated its workshop dedicated to the fabrication of Crust Alumina Feeding Devices…

Fives Aluminium Technical Institute is an advanced training center that has redefined the concept of technical education by combining mobility, practicality, and customized learning experiences.

This consortium, which brings together the world's leading expertise to implement an innovative process, aims to achieve a 50% reduction in direct CO2 emissions (excluding energy sources) from primary…